Solar energy has become an unstoppable force in the shift towards sustainable energy solutions, and at the forefront of this revolution is the monocrystalline solar panel. This guide aims to offer an in-depth look into these advanced solar panels, focusing on their manufacturing process, advantages, applications, and costs. We'll also touch upon aspects like working temperature and panel sizes, while discussing the critical differences between monocrystalline and polycrystalline solar panels.

Manufacturing Process of Monocrystalline Solar Panels

The journey of monocrystalline solar panels begins with the extraction of high-purity silicon. This silicon is then formed into cylindrical ingots through the Czochralski process, a method that ensures the silicon crystals have a uniform structure. These cylindrical ingots are then sliced into thin wafers, which are the building blocks of the monocrystalline solar cells. Each wafer is polished to remove any surface defects before being coated with an anti-reflective layer that enhances light absorption.

Brands like Jayuan are known for their meticulous manufacturing processes, ensuring that each solar cell performs optimally and has a long lifespan. Quality control is a crucial step in Jayuan's process, with each cell undergoing rigorous testing to meet industry standards.

Advantages of Monocrystalline Solar Panels

Monocrystalline solar panels boast several advantages over other types of solar panels, such as polycrystalline and thin-film panels. Here are some key benefits:

1. High Efficiency: Monocrystalline panels have the highest efficiency rates, often exceeding 20%. This means they can convert more sunlight into electricity compared to other types.

2. Space Efficiency: Due to their high efficiency, fewer panels are needed to achieve a specific power output, making them ideal for space-constrained installations.

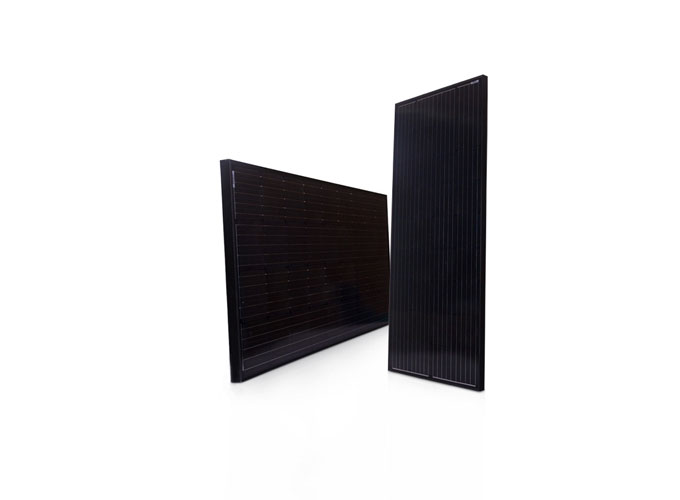

3. Aesthetic Appeal: These panels are generally more aesthetically pleasing, featuring a uniform dark appearance that blends well with various architectural styles.

4. Longevity: Monocrystalline solar panels typically come with longer warranties, often surpassing 25 years, indicating their reliability and long-term performance.

Applications of Monocrystalline Solar Panels

Given their efficiency and reliability, monocrystalline solar panels find applications in numerous sectors:

1. Residential: Perfect for homeowners looking to reduce electricity bills and carbon footprints.

2. Commercial: Businesses can use these panels to power their operations, reducing operational costs.

3. Industrial: Factories and warehouses with large roof spaces can significantly benefit from high-efficiency monocrystalline panels.

4. Off-grid and Remote Areas: Ideal for cabins, boats, and remote installations where grid electricity is not available.

Jayuan offers a range of versatile solutions tailored to meet the demands of these diverse applications, ensuring that users get the maximum return on investment.

How much do Monocrystalline Solar Cells Cost?

The cost of monocrystalline solar cells can be higher compared to other types, but the benefits often outweigh the initial investment. Typically, the cost per watt for monocrystalline panels ranges between $0.6 to $1.20, depending on the brand, efficiency, and market conditions. Jayuan, for instance, provides competitive pricing without compromising on quality.

Monocrystalline Solar Panel Working Temperature

Monocrystalline solar panels perform optimally within a certain temperature range. Generally, the optimal operating temperature for these panels is between 15°C to 35°C. Beyond this range, efficiency may drop slightly, but Jayuan ensures their panels are built to withstand extreme conditions, minimizing performance losses.

Monocrystalline Solar Panel Size

Monocrystalline solar panels come in a variety of sizes to meet different power requirements and space constraints. Common residential panels are around 65 inches by 39 inches, while commercial and industrial panels can be larger. Jayuan offers customized sizes tailored to specific project needs, ensuring that every square inch of available space is utilized efficiently.

Difference Between Monocrystalline and Polycrystalline Solar Panels

Understanding the difference between monocrystalline and polycrystalline solar panels is crucial for making an informed decision. Monocrystalline panels are made from single-crystal silicon, making them more efficient and aesthetically pleasing. In contrast, polycrystalline panels are composed of multiple silicon crystals, which makes them less efficient but also less expensive.

Monocrystalline panels are more suitable for installations where space and efficiency are paramount, while polycrystalline panels are often chosen for projects with budget constraints.

Conclusion

Monocrystalline solar panels are a testament to the advancements in solar technology, offering superior efficiency, longevity, and aesthetic appeal. Brands like Jayuan have perfected the manufacturing process, ensuring that consumers receive the highest quality products available. Whether you're a homeowner, business owner, or industrial operator, investing in monocrystalline solar panels is a wise step towards a sustainable future. If you're looking for monocrystalline solar cells for sale, Jayuan offers a range of options tailored to meet various needs and budgets.

By understanding aspects like the monocrystalline solar panel working temperature and assessing the monocrystalline solar panel size required for your project, you can make an informed decision that will pay dividends for years to come.